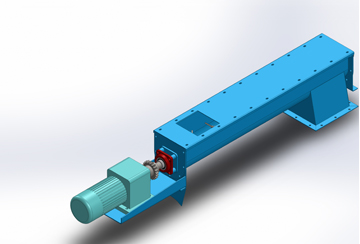

Pellet Mill Feeder And Conditioner

Feeder

The function of Screw Feeder is to stop, supply & regulate the feed from Pellet bin to pellet mill through conditioner. Screw speed is varied by use of A.C. Electronic Variable Frequency Drive. All parts coming in contact with feed are of stainless steel construction.

Conditioner

Conditioning is a process in which heat, moisture & liquid is introduced to the feed. It consist of a single or double barrel in which one or two agitators revolve & perform the blending action. The retention time in Conditioner can be controlled either by varying the speed of the agitator or changing the angle of agitating blades. It has been generally recognized that proper conditioning will provide following changes:

- Product becomes more pliable for pelleting which results higher output with low power consumption, better pellet quality and enhanced Die life.

- Increase starch gelatinization.

- Increased feed temperature promotes the reduction of harmful bacteria such as salmonella.

Gelatinization

Gelatinization is defined as the irreversible destruction of the crystalline order in a starch granule so that the surface of every molecule is made accessible to solvents or reactants.

As a result of gelatinization of starch, digestibility is improved considerably, because:

- Gelatinization enhances the ability of starches to absorb large quantities of water and this leads to improve digestibility in almost all cases and to improved feed conversion in many cases.

- Gelatinization increases the speed at which enzymes(amylases) can break down the linkages of starch to convert it into simpler and more soluble carbohydrates , including blood sugars(glucose).

To achieve complete gelatinization, following conditions must be met:

- Grinding should be reasonably fine to expose greater surface area for moisture and heat addition.

- Uniform blending of moisture as water, steam or both.

- Increasing temp of product and retaining it for time period.

Gelatinization is defined as the irreversible destruction of the crystalline order in a starch granule so that the surface of every molecule is made accessible to solvents or reactants.

It will have following features :

- Designed to provide retention time of 30 to 120 seconds or upto 240 sec, which can be selected directly from panel.

- Precise control of temperature through automatic control of steam.

- Design will be helicoid screw type which will guarantee first in first out and uniform thermal treatment to each particle.

- All feed contacting parts will be in SS304 construction for higher sanitation and low wearing.

- Up to 20% less energy consumption of the pellet mills as compare to conventional conditioners due to better conditioning.

- Better physical (hardness and durability) and chemical (gelatinization, pathogenic germs, etc.) quality of the pellets

- Better performance of the animals (production as well as health status)

All parts coming in contact with feed meal including barrel, shafts, blades etc. are made of AISI SS-304 Stainless Steel. Large access doors are provided on both sides with toggle clamps for quick and easy inspection, cleaning as well as maintenance. Depending on conditioning requirements, one two or three conditioners may be installed.